Marker Making

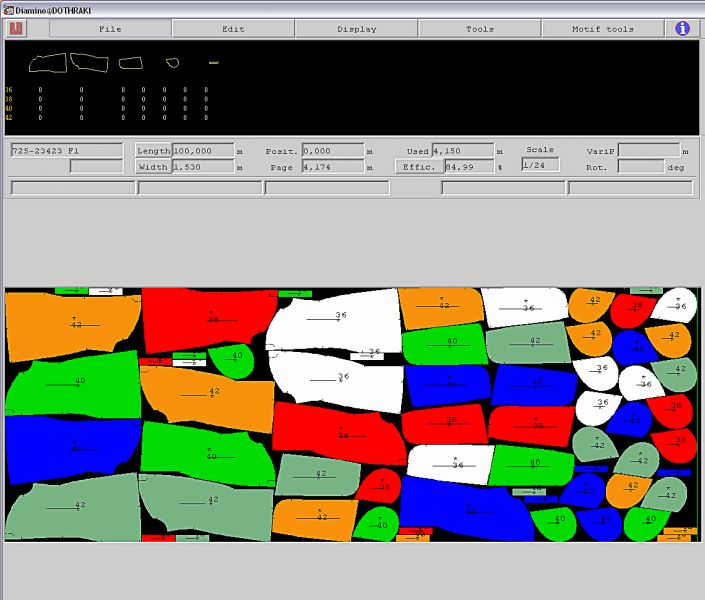

In the production process, the prior step of cutting operation is the marker making.

Increased efficiency of the fabric consumption is achieved by optimizing the positions of the pattern pieces on the fabric. The fabric saving achieved by streamlining consumption often covers the cost of the service.

The control over the costs associated with production is largely due to the marker making results. The expectated outcomes for this services are:

- Efficiency and lower average consumption on different fabric colors and types,

- Cutting lay plan sheets.

The Marketing Department may use our cost / consumption calculations to accurately determine the cost of the final product.

In the situations where average consumption is mandatory, marker making is the only way to achieve this goal.

In the situations where average consumption is mandatory, marker making is the only way to achieve this goal.

Depending on production production flows, files containing production markers can be:

- Printed on normal or thermo-adhesive paper;

- Converted into formats specific for the automatic cutting machines (.ISO; .GBR; .NC);

- Emailed to be inspected visually or for use on local equipment in the production section (.PDF format).